This month, since purchasing its EZ Fire Pro kiln, eco-friendly water filtration company, EcoPure Waters, celebrates three years of increased productivity in the manufacturing of its high-quality, custom-branded glass bottles.

In June 2019, EcoPure Waters purchased a new top of the range Northern Kilns EZ Fire Pro Front-Loading Kiln to help meet the demand of its growing client base for increased numbers of high-quality, reusable, custom-branded glass bottles.

The EZ Fire Pro can produce up to 500 branded glass bottles per eight to ten-hour shift, increasing EcoPure Waters’ daily bottle production capacity to over 1,000.

“Our new custom-built kiln (affectionately known as ‘Boris’ by our team) has increased both our bottle production capacity and efficiency”, said Paul Proctor, Director of EcoPure Waters. “The acquisition of the kiln was needed to meet the needs of our ever-growing client base for high-quality, custom-branded bottles, which are supplied alongside our range of water purification systems to provide an eco-friendly, cost-saving, ethical alternative to water provision. As well as increasing our bottle-producing capacity, we can now also produce large numbers of bottles more rapidly, reducing the (already fast) turnaround time from order to delivery”.

The EZ Fire Pro now sits alongside EcoPure Waters’ five smaller pottery kilns, each of which has capacity to hold up to 50 one litre-size bottles and is typically loaded up to twice in one eight to ten-hour shift. The new kiln has a capacity equal to all five smaller kilns, increasing the production capacity to 1,000 bottles per shift. This is a weekly capacity of 5,000, and an annual capacity of 260,000 (when operating one shift per day).

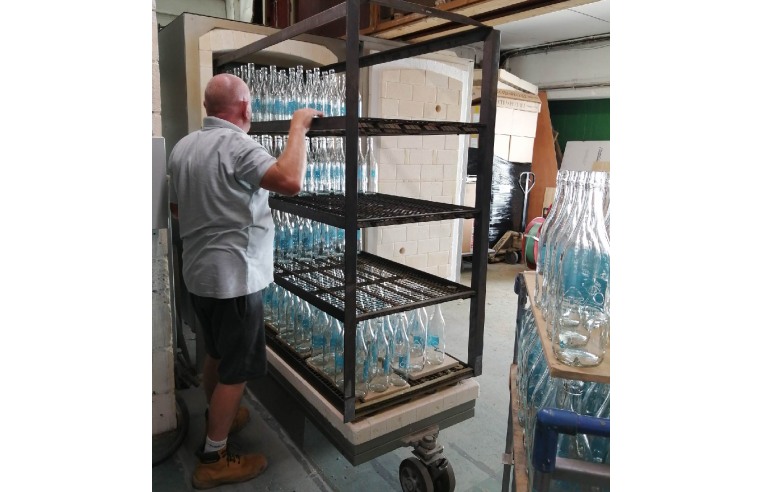

“In line with our company ethos, and to meet the expectations of our distinguished clientele, we wanted our new kiln to be as cutting-edge and technologically advanced as possible, offering the most efficient process and superior-quality end results as possible,” Proctor continued. “Features of the kiln include its 32 programmes, each with separate temperature control and auto damper temperature control, a removable, steerable truck base that is pulled out of the kiln for the efficient loading and unloading of bottles, 146mm of premium insulation, a lightweight 6mm stainless steel frame, and an innovative ergonomic design.

“As a niche operator providing a bespoke, hand-crafted product, the kiln’s state-of-the-art features are ideal in aiding our process of individual customer-focused quality control, from bottle design through to silk screen production and print, and then on to the firing of the bottles themselves. We are delighted with the results our new kiln is yielding – it has enabled us to meet the high demand of our growing client base and, with further growth anticipated in the years ahead, we look forward to supplying new and existing clients with our exceptional-quality, custom-branded glass bottles.”

Production in the kiln’s first year of operation was approx. 180,000 bottles. Today, EcoPure Waters is producing around 200,000 bottles per year, a figure that continues to rise as demand from the hospitality industry increases post Covid-19.

EcoPure Waters has been manufacturing, supplying, and maintaining market-leading water purification systems and custom-branded glass bottles for over 25 years, helping over 700 clients worldwide save money, reduce environmental impact, and create powerful branding opportunities. To find out more about EcoPure Waters.